digital thread

What is a digital thread?

A digital thread is a data-driven communication framework that connects traditionally siloed elements in manufacturing processes and provides an integrated view of an asset throughout the manufacturing lifecycle. In addition to technology, the establishment of a digital thread requires business processes that help weave data-driven decision management into the manufacturing culture.

Digital threads capture and share data across processes using a range of technologies, such as computer-aided design software, product lifecycle management systems and internet of things (IoT) sensors.

Digital thread vs. digital twin

The terms digital thread and digital twin are related concepts used in the context of manufacturing systems, but they refer to different aspects of a product's lifecycle.

A digital thread functions as a communication framework that makes it easier for asset and product data to flow smoothly throughout their lifecycles. A digital twin is a virtual model or a digital replica of an actual physical object or system and offers a more detailed view for analysis and optimization.

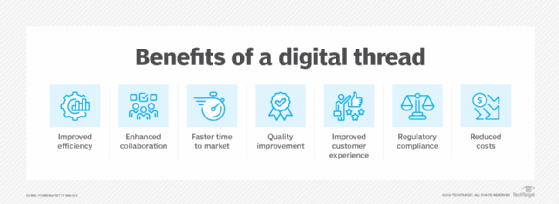

A digital thread provides the following benefits:

- Improved efficiency and operational agility. A digital thread streamlines data flow by integrating information across different stages of the product lifecycle. This reduces manual errors and redundancies and enhances operational agility.

- Enhanced collaboration. A digital thread boosts communication and collaboration across different departments and stakeholders involved in the product lifecycle. It reduces communication barriers so teams can access and contribute to a centralized and current digital representation. A digital thread also optimizes connectivity between manufacturing and engineering processes.

- Faster time to market. A digital thread speeds up the product development cycle by enabling collaborative and parallel workflows. This accelerated strategy can result in new products being launched faster.

- Quality improvement. A digital thread enables continuous monitoring and access to real-time digital data throughout the product's lifecycle, helping to improve quality control. Organizations can detect and resolve errors early in the process, resulting in higher-quality products.

- Improved customer experience. The information an organization acquires via a digital thread can be used to help it improve compliance and customer service initiatives. Businesses can learn more about how consumers use their products and pinpoint areas for improvement.

- Regulatory compliance. Organizations can better fulfill their regulatory requirements by keeping a digital thread, as it provides an auditable and traceable record of the entire production and product development process.

- Reduced costs. The features of digital thread technology -- such as workflow automation, analytics and reporting -- eliminate the need for manual labor, leading to increased efficiency and reduced labor-related costs.

![This image shows seven benefits of a digital thread.]()

A digital thread provides various benefits in the manufacturing processes.

The benefits of a digital twin include the following:

- Real-time monitoring. A digital twin enables real-time monitoring of physical IT assets, providing traceability and tracking of assets. Organizations can increase operational efficiency by tracking performance, identifying anomalies and reacting quickly to changes or problems.

- Cost savings. A digital twin can provide substantial cost savings. By using predictive analytics and simulations, organizations can identify and address potential issues before they occur and before the construction of physical prototypes, reducing maintenance costs and improving resource allocation.

- Improved design and development. A digital twin offers a testing and simulation platform during the product development and design stages that promotes innovation and product development.

- Improved time to market. By offering a virtual environment for design validation and testing, a digital twin promotes innovation and product development. Before physical manufacturing begins, organizations can evaluate performance, simulate various situations and make well-informed decisions that can shorten time to market and improve product quality.

- Optimized supply chain and inventory management. With the ability to provide real-time data on inventory, demand trends and production processes, a digital twin can enhance supply chain and inventory management systems. As a result, businesses can increase supply chain agility, lower inventory costs and forecast more accurately.

Together, both digital threads and digital twins contribute to a comprehensive and connected approach to product development and are vital tools for businesses that want to initiate or accelerate their digital transformation.

Challenges of a digital thread

A digital thread also has unique challenges, especially during setup. Some key challenges associated with the execution of a digital thread include the following:

- Disparate environments. Technology vendors, not-for-profit organizations and individual organizations are working to address the challenges of creating digital threads in disparate digital manufacturing environments. One challenge is simply that partners in the supply chain can range from large, fully digital manufacturers to small shops that don't have a single piece of digital equipment. The lack of standard protocols and messaging standards also hinders the information exchange needed for a digital thread.

- Data governance and management. During the creation of a digital thread, it can be challenging to manage and regulate the massive amounts of data produced throughout a product's lifecycle. To conquer this, organizations must develop strong data management procedures, including data quality assurance, security and privacy safeguards.

- Geographical and organizational data silos. Data silos can create problems for organizations as well as for suppliers, dealers and customers outside the company. Suppliers, clients and intermediaries such as dealers and third-party brokers must exchange data and information. Also, different geographical limits and data privacy laws and regulations determine what data can and can't traverse those boundaries.

- Data formats and standardization. For seamless data exchange, it's imperative to establish common standards and data formats across different systems and stakeholders. Lack of standardization can lead to data inconsistencies and hinder the effectiveness of the digital thread.

- Adoption and resistance to change. Any time a digital thread is introduced, a major change in workflows, processes and organizational culture is required. However, employee resistance to change could result in inefficiencies and delays if they aren't handled well. Successful execution of a digital thread requires effective change management, which includes addressing concerns, offering sufficient training to employees and creating an innovative culture.

A brief history and future outlook of digital thread

While there's no precise moment of inception, the concept of a digital thread can be traced back to the Global Horizons 2013 report by the U.S. Airforce Global Science and Technology Vision task force. This report associated digital thread with the concept of digital twin. In essence, the military aviation sector was the driving force behind the digital thread concept. It aimed to use digital technology to apply lessons learned to existing and upcoming programs to improve program performance.

Victor Singh and Karen Willcox of the Massachusetts Institute of Technology furthered the development of digital thread in their work Engineering Design with Digital Thread published in 2018.

The concept of digital thread has evolved in tandem with technological advancements, such as artificial intelligence and industrial IoT. It responds to the growing demand for integrated and collaborative approaches to both product development and lifecycle management. For example, the goals of smart manufacturing and Industry 4.0 are now being aligned with the idea of the digital thread, which is attracting attention to this trend outside of the aerospace and defense sectors. As such, digital thread is expected to become a significant advantage for future operating models and revenue streams.

Industry 5.0 is poised to integrate human, social and environmental aspects, envisioning a future where robots and machines collaborate seamlessly with humans. Explore the realm of Industry 5.0 and discover the possibilities it holds for the future.