Guide to supply chain management

The pandemic showed what can happen when the unimaginable breaks apart global supply chains and disrupts life as we know it. Effective supply chain management can restore order.

The products that support modern societies are manufactured and distributed by some of the most far-reaching systems ever built. A global network of supply chains brings us everything from the produce and packaged goods that fill supermarket shelves to the chips that run our smartphones and the raw materials of new construction.

It took a worldwide health crisis to make us realize just how fragile these global supply chains are.

Now, two years after the start of the COVID-19 pandemic, economies are recovering but supply chains remain sluggish and weak. Factories run at below capacity because they can't get raw materials or workers. Containerships back up at ports, and there aren't enough truckers to carry goods cross-country. The chaos has made supply chain a household word and supply chain management a top priority for many companies.

Supply chain management is a broad field that encompasses all of the processes, systems and strategies for optimizing a product's creation and distribution. Its many facets include demand planning, inventory management, logistics, procurement and supplier management. Developed as a manual paper process more than century ago, when early 20th-century industrialists needed to optimize manufacturing, supply chain management is now tied inextricably to 21st-century technology. But, as the pandemic has revealed, without global integration and accurate data, technology is as likely to cause supply chain failure as it is to prevent it.

Restoring the global supply chains that have been upended by the pandemic will not be easy. This comprehensive guide to SCM explains the essential terminology, processes, trends and challenges you need to understand to ensure that supply chain technology rises to the challenge. As you read this overview, click on the hyperlinks for in-depth information and advice on the key topics.

Supply chain management steps

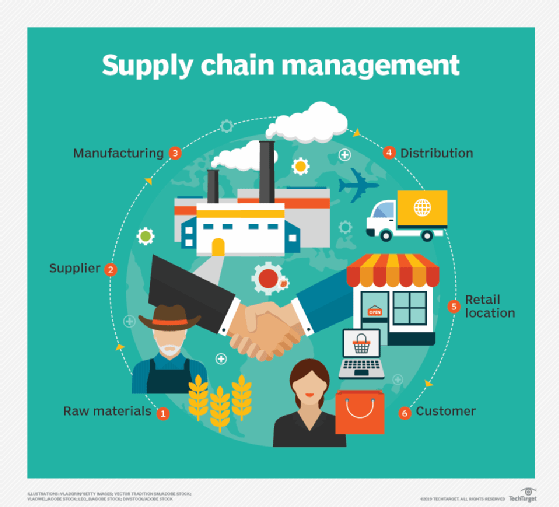

Each major phase of a product's movement through the supply chain, from materials to production and distribution (see Figure 1), has its own distinct business processes and disciplines. Most of the processes, which began as paper-based methods, are now usually handled in specialized supply chain management software.

Here is a step-by-step description of what goes into supply chain management.

1. Demand planning

The SCM process starts with figuring out what products customers want. This phase involves the early stages of supply chain planning, traditionally considered one of the two overarching categories of SCM along with supply chain execution.

Supply chain planning starts with demand planning, a process for gathering historical data, such as past sales, and applying analytics and statistical modeling to create a forecast or demand plan that the sales department and operational departments -- for example, manufacturing and marketing -- can agree on. The forecast determines the types and quantities of products to be manufactured. Getting the forecast right is critical for avoiding costly problems such as the bullwhip effect, in which small fluctuations in retail demand are magnified further up the supply chain, leading to severe shortages or surpluses of inventory.

Some companies perform demand planning as part of a formalized process called sales and operations planning (S&OP), which encompasses an iterative process of data gathering, discussion, reconciling of demand plans with production plans, and management approval. Some companies include S&OP in a broader process called integrated business planning (IBP) that incorporates other departments' plans in a single companywide plan.

2. Production planning

In the next major step, production planning, the company nails down the specifics of where and how the products called for in the demand plan will be manufactured. (Production planning is also used in other industries, such as agriculture and oil and gas.) A more fine-tuned variation called advanced planning and scheduling (APS; alternatively, APO for optimization) seeks to optimize the resources that go into production and make them more responsive to changes in demand. It is typically automated in specialized software.

3. Material requirements planning (MRP)

MRP is a process dating back to the 1960s that most manufacturers use to ensure sufficient materials and components, such as subassemblies, are available for use in the manufacturing process by taking inventory of what's on hand, identifying gaps, and buying or making the remaining items. The central document in both MRP and production planning is the bill of materials (BOM), a complete list of the items needed to make a product.

MRP is sometimes done as part of manufacturing resource planning (MRP II), which broadens the MRP concept to other departments such as HR and finance. MRP and MRP II were the predecessors of enterprise resource planning (ERP), which is designed to integrate the major business processes of companies in any industry. As you'll see, ERP software has become integral to SCM.

4. Inventory management

Inventory management consists of various techniques and formulas for ensuring adequate supply -- from raw materials in a manufacturing plant, perhaps managed in an MRP system, to packaged goods in a retail store -- for the least expenditure of time and resources.

Manufacturers are faced with a variety of inventory management issues, many of which involve coordinating demand planning with inventory at both ends of the production process. For example, sometimes MRP leads to more inventory -- especially when the system is first implemented -- and the manufacturer must work to synchronize MRP parameters with the inventory already on hand.

5. Procurement

Sometimes called sourcing, procurement is the process of finding suppliers for goods, managing those relationships and acquiring the goods economically -- along with all the communication, such as sending out requests for bids, and paperwork, including purchase orders and invoices. It is a major area of supply chain management, given how much is bought and sold at all points along the chain. Most players in the supply chain -- suppliers, manufacturers, distributors and retailers -- have dedicated procurement staff.

Strategic sourcing is an elevated and more sophisticated type of procurement that aims to optimize a company's sourcing process by taking advantage of its consolidated purchasing power and aligning it with business goals.

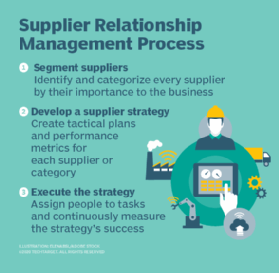

Supplier relationship management (SRM), in contrast, addresses sourcing issues by focusing on the suppliers the company deems most critical to success and systematically strengthening relationships with them while fostering optimal performance. Figure 2 shows the SRM process in brief.

6. Logistics

Logistics covers the transporting and storing of goods, from the delivery of parts and raw materials to manufacturers or processors to the delivery of finished products to stores or direct to consumers, and even beyond for product servicing, return and recycling -- a process called reverse logistics. Inventory management is threaded throughout the logistics process.

Importance of supply chain management

Effective SCM -- or lack thereof -- can have a significant impact on companies, individuals and society.

SCM typically improves customer service and ensures customer satisfaction by making certain the right products are available on time at the right locations. By increasing customer satisfaction, companies can build loyalty, which usually leads to more sales over the long term.

SCM can also reduce company operating costs by cutting expenses on purchasing, production and the entire supply chain. Lower costs improve a company's financial position by increasing profit and cash flow. Furthermore, following supply chain management best practices can minimize overuse of large fixed assets -- such as warehouses and vehicles -- by, for example, allowing supply chain experts to redesign their networks to maintain customer service levels while operating fewer warehouses.

SCM's impact extends well beyond a company's bottom line. It can help ensure human survival by improving healthcare and protecting people from climate extremes. People rely on supply chains to deliver necessities such as food and water as well as medicines. The supply chain is also vital to the delivery of electricity to homes and businesses, providing the energy needed for light, heat, air conditioning and refrigeration.

SCM can improve the quality of life by fostering job creation, providing a foundation for economic growth and improving standards of living. It provides a multitude of job opportunities, since supply chain professionals design and control all of the supply chains in a society and manage the labor-intensive functions of inventory control, warehousing, packaging and logistics.

Furthermore, a common feature of most poor nations is their lack of developed supply chains. Societies with strong, developed supply chain infrastructures -- such as large railroad networks, interstate highway systems and an array of airports and seaports -- can efficiently exchange goods at lower cost, allowing consumers to buy more products, thus fostering economic growth and increasing the standard of living.

Want more SCM tips? Check out this book excerpt on supply chain management best practices.

Levels of supply chain management

Some experts find it helpful to divide SCM into three broad levels that categorize its functions and help ensure that it serves business goals: strategic, tactical and operational.

Strategic SCM takes in the entire scope of a company's supply chain network and processes. It addresses the major long-term elements in a comprehensive strategy, including the type and number of facilities, technologies and suppliers.

The tactical level nails down the specific means of executing the strategy, be they production schedules, logistics processes, contracts or software applications. Time horizons are shorter than in strategic SCM. Here's where standards and best practices are identified for key deliverables such as customer service, efficiency and cost.

The operational level encompasses the daily operations of SCM. Forecasting, production scheduling, shipping and invoicing are typical operational tasks.

Interestingly, some observers say the globalization of manufacturing has turned SCM into a mostly strategic function as longer, more complex supply chains present challenges and opportunities that require much more planning and analysis. In this view, the tactical and operational levels mostly focus on logistics.

The three levels influence each other. A strategy is just an idea if it isn't translated into tactics and operations. Conversely, operational decisions and tasks can be wasteful, ineffective or risky if they conflict with the organizing principles of the tactical level and the larger goals and mechanisms in the strategy.

This three-level SCM approach is critical in building supply chain resilience for handling disruptions such as the COVID-19 pandemic. To cite a prominent example, the unavailability of supplies that would normally ship from virus hotspots and lockdown areas required manufacturers and retailers to drop their longstanding preference for the cost savings gained from using just-in-time inventory models, and instead give priority to storing safety stock closer to customers -- with less regard to the cost. Availability of supply became paramount.

Goals of SCM

As supply chain management has matured and the technology that powers it advances, its importance to businesses operations keeps growing. The goals companies hope to achieve by using supply chain management to optimize the flow of goods and materials include the following:

- cost savings from acquiring goods and services as cheaply as possible and minimizing expenses on capital goods, such as inventory, facilities and equipment;

- efficiency that comes from avoiding waste and duplication;

- revenue increases from meeting higher levels of demand with sufficient supply;

- profit from lower costs and higher revenue;

- customer satisfaction from balancing supply and demand, and delivering the products consumers want;

- quality improvements from sourcing better materials, avoiding production errors and gathering customer feedback; and

- stability from effective risk management, visibility and collaboration.

Advantages

Besides helping companies reach the usual goals of SCM, the improved efficiency, coordination and quality that come from mastering the planning, control and execution of supply chain processes can produce secondary advantages, including the following:

- better relationships with suppliers, distributors and retailers;

- improved brand image;

- environmental sustainability;

- improved cash flow;

- safer products and services;

- lower overhead;

- improved accountability and compliance; and

- more innovation.

Challenges

Because SCM is inherently complex, it is difficult to execute at a consistently high level. Thus, complexity itself is the biggest challenge facing practitioners, who are also challenged by not having enough information, technology, labor, skills, time and resources to stay on top of every area of supply chain management.

A survey of 50 companies by Michigan State University and APICS, a prominent supply chain association, identified six challenges that keep executives up at night:

- Capacity and resource availability. Executives worried they wouldn't have enough people, facilities, IT capabilities and other resources to support growth.

- Talent. Hiring or retaining industrial engineers and other supply chain professionals was a major concern.

- Complexity. New products and expanded product options create pressure to find new suppliers. The growth in omnichannel commerce, especially direct-to-consumer channels, called for deploying new systems and threatened longstanding success in traditional channels such as wholesale.

- Threats. Respondents cited risks from natural disasters, the failure of key suppliers, rogue employees who cause or call attention to supply chain disasters, product recalls and inadequate planning for business continuity.

- Compliance. Fast-changing product regulations, international trade rules and inconsistent customs enforcement made compliance demands too numerous and complex to manage.

- Cost and pricing issues. Downward price pressure in industries such as healthcare, pharmaceuticals and raw commodities put pressure on suppliers to minimize their costs.

Volatility is another common challenge, as sharp changes in supply or demand -- or both at the same time -- can strain supply chains and create new challenges such as shortages, delays, surpluses, spoilage and price gouging, to name only a few.

COVID-19 shows the importance of supply chain risk management

Few events have brought as much volatility as the COVID-19 pandemic to both ends of the supply chain and nearly every stage in between. The disruptions caused by the pandemic have exposed the risks that lurk beneath the surface of modern supply chains. Consumers now see how easily the world's intermodal shipping system can collapse when one mode of transportation bogs down or fails. Companies have learned hard lessons about offshoring too much of their manufacturing and over-relying on a handful of suppliers. One result is the renewed interest in supply chain risk management tools and strategies.

The fallout from COVID-19 has also elevated other supply chain risks that often are ignored. Privacy and security, for example, have grown in importance as more supply chains become digitized. The challenge is acute because supply chains can involve thousands of participants, including local suppliers working from remote network endpoints that can be entry points for hackers to attack the global supply chain network.

Such supply chain cybersecurity risks increased when more people began working at home due to COVID-19. With more products such as home Wi-Fi routers and printers logging on as endpoints on the internet, and other more expensive products from farm tractors to factory robots increasingly equipped with live connectivity for their manufacturers' product-as-a-service offerings, the number of endpoints is growing exponentially. Extending the digital supply chain comes at a cost.

SCM vs. logistics, operations management and ERP

Supply chain management is closely related to several other disciplines, so much so that people sometimes confuse them. Here is a brief guide to keeping them straight.

Logistics is an essential component of supply chain management, the part that deals with moving products and materials in activities such as transportation, warehousing and distribution.

In contrast, SCM addresses a much broader range of planning processes involved in deciding which products to make in the first place, how to make them and in what quantities, and the potential demand for them. SCM takes a holistic view of the entire supply chain and its many participants -- especially, and unsurprisingly, suppliers -- and how to coordinate their activities. Logistics is mostly limited to the transportation and warehousing aspects.

ERP is software for managing all aspects of a business, particularly financial and human resources. While many ERP suites have sophisticated modules for most aspects of SCM, as well as subcomponents such as inventory management and MRP, other ERP systems are designed for companies with supply chains that are so minimal they mostly involve office supplies and furniture.

SCM is one of the biggest components of an ERP suite. It goes beyond the basic financials, HR, sales, order management and purchasing that all companies have in common to include the next tier of related but often much more complex business processes, such as customer relationship management and product lifecycle management. Manufacturers, retailers and distributors are the biggest buyers of ERP suites that also have SCM capabilities. However, it's common for companies to buy their SCM suite from one vendor and ERP from another.

Operations management is the discipline devoted to maximizing the efficiency and effectiveness of the operations that result in products or services. It has everyday applications to supply chain management and manufacturing, especially inventory management, production planning and MRP. Lean manufacturing, Six Sigma and the continuous improvement methodology Kaizen are products of operations management research. Most senior supply chain and manufacturing managers are trained in operations management.

History of supply chain management

This interweaving of logistics, operations management, SCM and ERP makes a lot more sense when you know a little about the history of supply chain management.

While its earliest roots really go back to the pioneering industrial engineering research of the early 1900s, SCM is generally regarded to have started with operations research that was done to solve the complex military logistics problems of World War II. Research in the post-war years began to tackle how to optimize the mechanical and physical aspects of material handling and warehousing to make them less labor-intensive. Trucking was added to the mix, creating a unified discipline for managing distribution.

Manual records and calculations began to be more automated with the wider availability of computers in the 1960s and 1970s. Researchers could now use a software system to test their theoretical models and calculations to optimize inventory and truck routes.

When personal computers exploded on the scene in the early 1980s, logistics planners soon had electronic spreadsheets and maps at their disposal and began to design entire supply chains. Computer control of material-handling machines, such as conveyor belts, debuted and algorithms were now used in airline scheduling. Much of this operations management and logistics research made its way into commercial use as corporate executives began to see the importance of optimizing logistics management and hiring specialists for the work.

All this time, MRP had been developing on a separate track, was a standard tool of manufacturers and usually managed in software. When ERP software became popular in the 1990s, manufacturers and distributors then had a digital system with process integration that unified logistics, production management, MRP and financials on a single database. APS and other modules were added to make ERP suites comprehensive systems for automating most of SCM.

SCM software and tools

Besides the aforementioned comprehensive SCM suites, which are available standalone or as part of ERP suites, there are numerous niche products and ERP modules for the common SCM processes named above: APS, demand management, inventory management, MRP, production planning, procurement and sourcing, S&OP and SRM. In addition, some vendors offer order management systems designed to integrate the workflow of customer orders from receipt to fulfillment and payment.

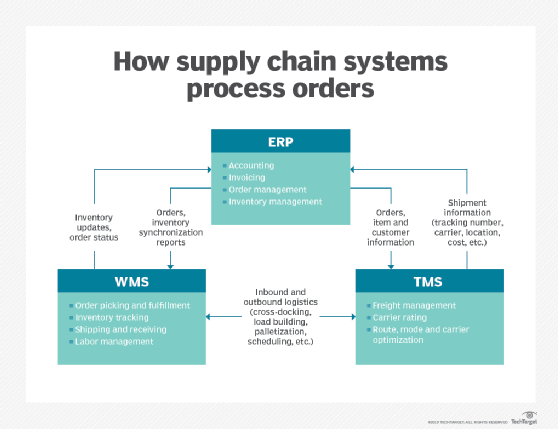

While many ERP and SCM suites come with logistics features, especially warehouse and inventory management, many companies opt for specialized software -- two kinds in particular:

- A transportation management system (TMS) is essentially a repository of detailed information about shipping carriers that enables users to plan, execute and track shipments.

- A warehouse management system (WMS) is software for managing the many processes involved in moving goods through warehouses, such as inventory tracking, receiving and putaway.

Figure 3 shows how ERP, WMS and TMS software coordinate order processing and delivery.

Usually there is a small set of important tools that works alongside the SCM software. Typically, the ERP or SCM suite has its own reporting module for collecting information and presenting it in readable form. Separate business intelligence (BI) and analytics platforms, which work with nearly every type of business software, give users more sophisticated tools to find and analyze information about their supply chains.

Increasingly, analytics is embedded throughout the SCM suite and doesn't require accessing a separate BI tool. In recent years, there has been a strong drive to deploy supply chain analytics to find patterns in the information in orders, shipments and other data sources to improve the accuracy of demand planning and make supply chains more responsive and efficient.

Emerging technologies in SCM

Other information technologies -- especially big data, predictive analytics, artificial intelligence (AI), internet of things (IoT), robotics and autonomous vehicles -- are increasingly being used to help solve such modern challenges as supply chain risk and sustainability. Most of these emerging technologies have the common goals of making it easier to gather more detailed supply chain data and analyze and act on it quickly. If these technologies take hold, future supply chains will be largely automated, transparent and perhaps resilient enough to withstand the next pandemic.

Here are three examples of how emerging tech can help protect and sustain supply chains:

- IoT logistics technologies can aid transparency and traceability to help boost food quality and safety by using sensors to monitor the temperature of perishable food while it's in transit. Predictive analytics, augmented by the machine learning and natural language processing of AI, can anticipate problems and sometimes address them without human intervention.

- Blockchain -- distributed electronic ledgers -- can guarantee the accuracy and ownership of documents used in supply chain logistics and the millions of other documents exchanged every day throughout the global supply chain. Many of the early blockchain supply chain use cases involve improving traceability in the sourcing of raw materials and crops for improved food safety and sustainability.

- Digital twins are another emerging technology that could improve agility and help manage risk. Defined as digital representations of a thing, person or process, digital twins are initially being used -- starting in the product development stages -- to manage data and maintenance of expensive equipment, such as mining trucks and factory assembly lines. They could also improve product data management (PDM) and make that data more useful in supply chains. Some companies are working on digital twins that model their entire supply chain and use prescriptive analytics to alert people to problems. Digital twins also serve as data brokers between IoT sensors and the ERP and SCM software.

Globalization in SCM

Most supply chains are global, since it's rare for both the demand and supply sides to exist entirely in one country or even one continent. Global interdependence is the norm and is all but certain to continue despite disruptions such as earthquakes, wars and pandemics that break some links in the chain.

The effects of the COVID-19 pandemic illustrated this interdependence like never before. To take just one example: Food supply chain disruptions forced agriculture companies and local distributors alike to emphasize geographic diversity in suppliers and reconsider product selection to ensure availability.

Major shifts have occurred in the decades since the globalization of manufacturing took off in the 1990s. Factories have mostly moved from North America to the Far East, but some have started to return. Consumer markets have exploded along with growing economies in developing nations and China, representing a shift in the demand side and yet another reverse in direction of the flow of manufactured goods.

Globalization makes supply chain sustainability, resiliency and visibility all the more essential, and networked SCM technology will be the primary means of achieving them. You might say modern supply chains couldn't exist without the digital technologies to manage them.

Senior site editor Diann Daniel contributed to this guide.