RPA and AI strengthen weak links in supply chain workflows

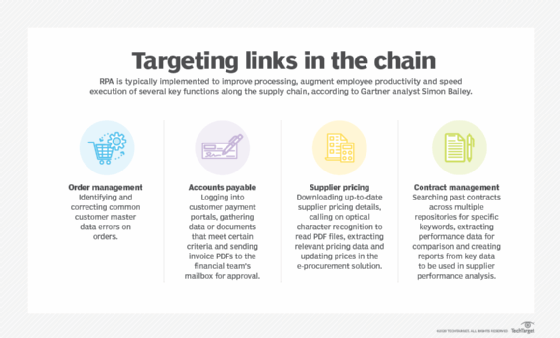

Instead of an all-or-nothing approach to supply chain automation, RPA is most effective when targeted at subprocesses to improve high-volume, repetitive, error-prone tasks.

Streamlining and speeding up high-volume business processes along the supply chain is essential to a company's financials, product inventories, purchase orders, transactions, deliveries and fulfillments as well as analytics functions. Much of these functions are repetitive and prone to human error.

Robotic process automation tools can help automate many of these tasks to reduce errors and free up humans to work on more valuable and interesting projects.

RPA and AI can also complement other technologies to improve business decisions, parse documents and predict risk. RPA does have its limitations, but they can be addressed by the right mix of tools and human judgment.

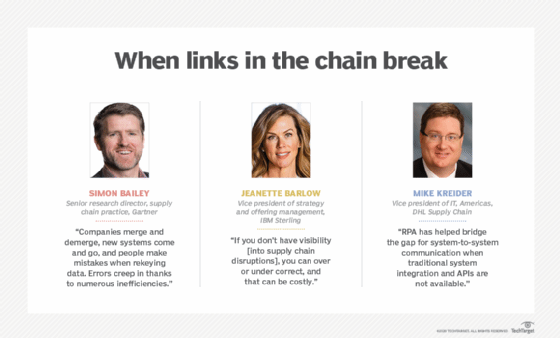

"We've seen RPA technology become more widely adopted in daily supply chain operations," said Mike Kreider, vice president of IT Americas at DHL Supply Chain, headquartered in Bonn, Germany. DHL is using RPA to automate manual data entry functions, generate supply chain status updates and perform system-to-system audit functions. "RPA has helped bridge the gap for system-to-system communication when traditional system integration and APIs are not available," Kreider added. Complex supply chain functions can be processed more easily across ERP, transportation and warehouse management systems.

Many manual processes are involved in the transportation business, including order entry, track and trace, appointment monitoring and generating proof of delivery for customers. DHL has created eight RPA software robots running out of a centralized control tower in Detroit to support customers. Kreider reported that the company is saving hundreds of man-hours per day on repetitive tasks, such as looking up transportation delivery status in carrier websites, generating email updates on delivery status, creating transportation orders from a list of ready-to-ship items and capturing proof-of-delivery documents from websites to update transportation management systems. "RPA is a mission-critical part of our service offering," Kreider said, "and has also helped us to eliminate paperwork, which has operational and environmental benefits."

For now, Kreider sees RPA at DHL used mostly in the back office and some front-line operations. "In the future," he noted, "I anticipate more advances in machine learning and AI will further improve the effectiveness of RPA tools and make them easier to program, which will likely lead to its use in other applications and processes in the supply chain."

Multi-problem solver

Any type of glitch or bottleneck along the supply chain route can slow critical processes and cause costly errors. RPA helps to mitigate various types of inefficiencies. Supply chains have many end-to-end processes, such as "order to cash" and "procure to pay," and many subprocesses like "order capture" and "pay invoice."

"Where possible, digital data will be passed effortlessly from system to system," said Simon Bailey, senior research director, supply chain practice, at Gartner. "But companies merge and demerge, new systems come and go, and people make mistakes when rekeying data. Errors creep in thanks to numerous inefficiencies."

Each type of inefficiency can lead to a variety of problems throughout the supply chain:

- System inefficiencies are driven by a lack of interconnectivity, manual process or system configurations.

- Data inefficiencies are driven by misaligned data between customer and supplier, incorrect or missing master data within one enterprise or delays in updating transactional data, such as price changes.

- Policy inefficiencies are driven by differences in how vendors and suppliers view such policies as customer payment terms.

- People inefficiencies are driven by organizational design, inconsistent roles and responsibilities, and over-worked, disengaged, distracted or distressed employees.

Breaking complex processes into subprocesses built from simple tasks can help eliminate bottlenecks. RPA is best at automating the movement of structured data used in standardized tasks across multiple, stable systems, especially highly repetitive tasks -- not processes -- that require high volumes of rekeying with greater potential for errors.

"RPA," Bailey explained, "can execute scripted tasks around the clock, faster, with fewer errors and at less cost than manually executing the same process for tasks that are routine, repetitive, rule-based and predictable -- and least effective when this is not the case."

Overcoming disruptions with RPA and AI

Supply chain strategy wasn't getting a lot of attention from executives before events of the past year. But it is now due to the real and potential supply chain disruptions caused by the COVID-19 pandemic as well as Brexit and a brewing trade war between the U.S. and China.

Effectively bridging data silos is one way to overcome these disruptions, according to Jeanette Barlow, vice president of strategy and offering management at IBM Sterling. Companies have typically deployed separate systems for transportation management, warehousing and third-party logistics, making it more difficult for management to make assessments of disruptions. "If you don't have visibility, you can over or under correct, and that can be costly," Barlow reasoned.

RPA can help to fill these visibility gaps across systems, particularly for businesses that deal with several smaller business partners. A major company, for example, can have a number of large retail clients with thousands of small suppliers that rely on different invoicing systems. RPA, in conjunction with other technologies, could determine why an invoice looks different than expected and help reduce the time humans spend disputing it and ensure that suppliers get paid on time.

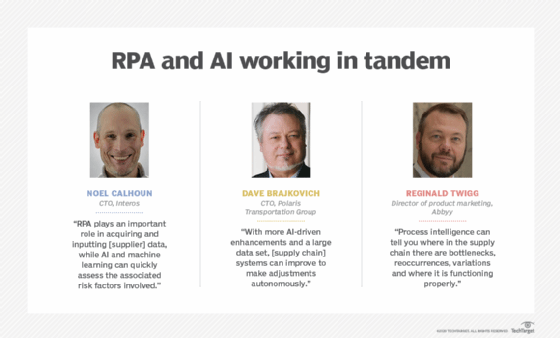

Many supply chain decisions involve sourcing origin and cost. In the wake of COVID-19, massive amounts of supplier data that can affect risk assessment are continuously changing. "RPA plays an important role in acquiring and inputting this data, while AI and machine learning can quickly assess the associated risk factors involved," said Noel Calhoun, CTO at third-party risk management software maker Interos.

Since RPA is not effective at making predictions on its own, he said, AI and machine learning capabilities can help address this need. RPA and AI, for example, could be used to improve the sourcing speed and accuracy of risk-related data, with machine learning plugged into this data to help provide recommendations on alternative supplier options that improve supply chain management.

Boosting logistics with AI

RPA excels at copying and pasting data between applications, but it can struggle with comprehending paper documents from business partners using different formats. In addition, RPA bots can break when processes change.

Polaris Transportation Group, a logistics, warehousing and distribution service headquartered in Mississauga, Ontario, has been combining RPA with various AI modules to address these limitations, according to CTO Dave Brajkovich. Polaris manages large amounts of paperwork associated with less-than-truckload shipping -- a highly labor-intensive process that can get even more complex with cross-border shipments. The company decided to automate repetitive processes like order entries and customs broker packages, Brajkovich said.

Intelligent document processing uses AI and machine learning to automatically produce 80% to 85% of the documents. Brajkovich hopes to reach 90% as the company improves the process for tagging documents to update the AI algorithms. "This is where digital workforce staff members continue enhancing the process by interacting with the application and bots," he explained. RPA also improved the generation of key performance indicators. "Instead of playing catch-up or missing things due to a lack of insights," Brajkovich noted, "we are always a step ahead of the process."

However, the rigors of making setups and changes to setups can hinder RPA. "This tech is still in the early adoption stage," Brajkovich said. "But with more AI-driven enhancements and a large data set, the systems can improve to make adjustments autonomously."

Procreating RPA bots

Supply chain processes using RPA and AI often evolve over time to adapt to the changing needs of business leaders, suppliers and customers. RPA was considered one of the fastest growing sectors in 2019, yet many enterprises faced challenges in scaling RPA deployments.

Gartner said it sees hyperautomation coming into play -- developing an end-to-end supply chain strategy to automate the process of creating new RPAs and "scale beyond the initial few low-hanging fruits of routine processes [that] cannot be solved by a single tool or with siloed strategies."

One emerging strategy is to use process mining and intelligence tools to identify all the tasks associated with key business processes to help prioritize automation efforts. Using AI for process mining and discovery ahead of deploying RPA is one of the easiest ways to make smart automation decisions, suggested Reginald Twigg, director of product marketing at digital intelligence tools provider Abbyy. "Process intelligence," he said, "can tell you where in the supply chain there are bottlenecks, reoccurrences, variations and where it is functioning properly."