vendor-managed inventory (VMI)

What is vendor-managed inventory (VMI)?

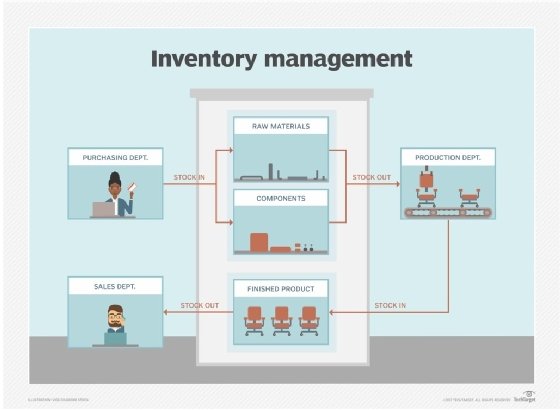

Vendor-managed inventory (VMI) is an inventory management technique in which the supplier of goods, usually the manufacturer, is responsible for optimizing the inventory a distributor holds.

VMI is an inventory management approach in which a supplier or vendor (the inventory seller) manages and maintains the inventory, even after the inventory is in the retailer's (the inventory buyer's) warehouse. The supplier takes all inventory-related decisions and replenishes inventory levels for the retailer.

With this approach, the vendor is responsible for minimizing the retailer's inventory stockout and overstocking risks. They do this by using inventory management software that allows them to set stock thresholds, monitor inventory levels, and maintain these levels at a targeted level.

How a VMI system works

With the VMI approach, the vendor owns the inventory but places it on the retailer's warehouse premises. VMI requires a communication link -- typically electronic data interchange (EDI) or the Internet -- that provides the supplier with distributor sales and inventory data necessary to plan inventory and place orders.

By sharing inventory data with vendors, retailers offload the tasks of determining order times, sizes and frequency to the vendor. The vendor uses this data, along with data about expected lead times, production levels, and estimated shipping delays, to replenish the stock as needed and ensure that inventory levels are optimized.

Traditional inventory management differs from VMI. Under the traditional arrangement, the distributor or retailer handles all inventory management tasks. To purchase new inventory, they create new purchase orders (POs). Inventory can be owned by the distributor, or supplier, often under consignment.

Vendor-managed inventory metrics

Before entering into a VMI relationship, the retailer and supplier agree on certain metrics or key performance indicators (KPIs) that help both parties make mutually beneficial decisions about the stock.

Some inventory management KPIs typically part of a VMI agreement include:

- Inventory turnover rate: The number of times the entire inventory is sold in a time period (e.g., one year), also known as inventory turns.

- Stock to sales ratio: The amount of inventory in storage versus number of sales.

- Sell-through rate: The number of inventory units sold versus the number received.

- Backorder rate: The number of delayed orders (orders the company cannot fulfill) as a percentage of the total orders placed.

- Supplier quality index (SQI): An aggregate metric that indicates the vendor's performance in terms of material quality, corrective action, delivery quality, etc.

Retailers and vendors also set the terms and conditions (T&C) that govern the VMI partnership. Payment terms, particularly around payment times, are covered in the agreement, addressing, for example, whether the retailer will pay for the stock when they acquire it or sell it.

Benefits of vendor-managed inventory

VMI system benefits include better inventory accuracy, forecasting, and service. It can also reduce inventory-related costs for both retailers and vendors because the vendor uses appropriate tools and software to manage inventory, replenish stock and reduce costly overstocking.

VMI also reduces stockout risks, making it less likely the retailer will lose achievable revenues from being unable to meet customer demand.

VMI also helps streamline a retailer's supply chain management (SCM) operations while reducing overhead and management burden for tasks such as creating POs whenever they need more inventory.

Finally, VMI can improve relationships between retailers and vendors. Retailers prefer to work with trustworthy vendors willing to tackle inventory management. VMI helps retailers avoid lengthy customer onboarding processes and helps vendors nurture long-term business opportunities.

Drawbacks of vendor-managed inventory

VMI can present challenges in communication, cultural resistance, and setting clear lines of responsibility. Communication issues are especially common when there are inventory changes, such as when the retailer introduces or removes products.

A lack of current inventory data can create problems like stockouts and overstocks. Inadequate or insufficient data can affect demand forecasts, which can make it difficult for the retailer to meet demand or adjust to sudden demand spikes.

However, the benefits of VMI far outweigh these concerns, especially if the VMI agreement is carefully planned and implemented in a transparent manner.

When should VMI be used?

The VMI approach is best used by retailers that (re)sell many types of products from many different vendors. When multiple vendors are involved, retailers find it burdensome to manage the incoming inventory from all of them. Shifting the responsibility for inventory management to various vendors reduces the burden. It also enables the vendors to proactively and quickly replenish the retailer's stock, driving their own continuous sales and revenues.

Who uses vendor-managed inventory?

Many companies use VMI, including retailers like Walmart and Home Depot, e-commerce firms like Amazon, and fast-moving consumer goods companies like Procter & Gamble.

Read about the top five inventory management techniques. Explore the differences between warehouse management system (WMS) vs. inventory management system and see how a WMS compares to an order management system. Check out nine benefits of material requirements planning software.